charpy impact test of steel 1045|charpy impact temperature test : exporters Tensile tests were performed on both the base metal and weld metal of a welded coupon composed of SAE/AISI 1045 and ASTM A572 steels. The fracture toughness was . Nous vous donnons votre propre serveur Minecraft, où vous pouvez jouer avec vos amis toute la journée et toute la nuit. Obtenez le vôtre maintenant Gratuitement

{plog:ftitle_list}

WEBLog In. Forgot account? · Sign up for Facebook. Log into Facebook to start sharing and connecting with your friends, family, and people you know.

standard charpy impact test

The standard EN 10 045 concerns metallic materials — Charpy impact test and comprises the following parts: — Part 1: Method of test; — Part 2: Verification of pendulum impact testing .

The quasi-static standard tensile, torsional, and combined tension and torsion tests were performed at room temperature to investigate the mechanical properties of normalized AISI 1045 steel.

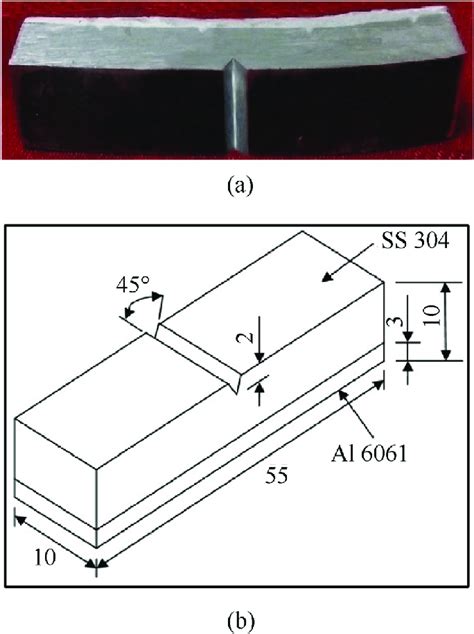

AISI SAE 1045 steel tenacity variation evaluation subjected to corrosion process by chloride using the Charpy pendulum machine. C G Cárdenas-Arias1,2, A D Rincón . Charpy impact tests were performed using weld cladded samples with the V groove in two positions, over the hardfacing layer and over the AISI 1045 substrate. The .

Tensile tests were performed on both the base metal and weld metal of a welded coupon composed of SAE/AISI 1045 and ASTM A572 steels. The fracture toughness was . Then the samples were tested for hardness, tensile strength, and toughness (Charpy test). The results show that the tensile strength decreases by 12.4%, 6.33%, and .Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, .Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient .

examples of charpy impact tests

One of the most prominent impact tests is the Charpy impact test that gives information regarding the behaviour of material under impact load [8], [9], [10]. Charpy test is a low-cost and reliable technique that measures the energy consumed in breaking a notched specimen simply supported at both ends when hammered by a swinging pendulum.Charpy Impact Test Laboratory Report EXPERIMENT I LAB REPORT SUBMITTED BY: GABRIEL RANIERI LUXO LAB MEMBERS: GABRIEL RANIERI LUXO . By doing this it was possible to observe the behavior . 1045 Normalized Round Bar Charpy Problem 1045 Normalized Round Bar Charpy Problem bflann (Materials) . 15% min elongation and cat. 3 Charpy Impact Testing with Min. absorbed energy of 27 Joules. . What is your minimum test temperature for CVN impact? Why is the 1045 steel being permitted when CAN/CSA G40.21 Grade 300W is specified? You .

1045 is a medium tensile low hardenability carbon steel generally supplied in the black hot rolled or occasionally in the normalised condition, with a typical tensile strength range 570 - 700 Mpa and Brinell hardness range 170 - 210 in either condition.Characterised by fairly good strength and impact properties, plus good machinability and reasonable weldability in the hot rolled or .The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be . Charpy V-Notch impact energy on dual phase 590 steel as well as AISI-1018 structural steel is presented. Tests were conducted at temperatures ranging from −120 °C (−184 °F) to 90 °C (194 °F). Specimens oriented in both L–T and T–L directions were tested for the DP590. Corrections for the reduced thickness was made and justified.

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy . the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two quenched and tempered 4340 steels (with different mechanical properties . steel is an 18 Ni maraging steel .

impact testing of mild steel, the Charpy Impact Test can provide information on how much energy a specimen such as mild steel can absorb under an impact scenario. In this context, the following sections will present information on: 1) impact testing; 2) effect of . In the Charpy impact test, since the maximum tensile stress near the V-notch in a specimen is assumed to be 3.9 times the σy, it is predicted via the stress-d −1/2 map shown in Figure 15 that a .A Charpy impact test (CVN test) is used to measure the fragile-ductile temperature and as a quality control test. This evaluation's simplicity allows converting energy values to fracture toughness .

Charpy impact test for steel 1045. What is the Brittle Temperature (Tb) of 1045 steel? The tensile temperature (Tt) of 1045 steel? What is Ductile Brittle Transition Temperature (DBTT) of 1045 steel? There’s just one step to solve this. Solution. Step 1. View the full answer. Answer. Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Instrumented Charpy impact test equipment can continuously record data on displacement, force, energy, time, etc., and save them in PC [15–18]. Therefore, further valuable information on the material . Furthermore, the tested steel tensile strength and V-notch impact toughness are more than 1500 MPa and 85 J, respectively [24]. It can be .The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point .

The 4140 steel has been subjected to Charpy impact tests to investigate the microstructural properties of this steel, Chaouch et al. (2018); the effect of quenching and tempering heat treatments .

charpy impact testing

Fracture surfaces of the impact Charpy test in the zone of the AISI 1045 substrate for the specimens weld cladded using GMAW-P and CMT in different metallurgical conditions for the notch in the top position are shown in Fig. 15. For the three conditions in both welding processes, it is possible to observe the presence of faceted areas typical .Explore the Charpy impact test method for metallic materials as specified by the European EN 10045 standard. Understand the test's purpose, procedure, and the significance of the energy absorbed in joules. Learn about the designations, test pieces, and testing machines used.completed impact tensile testing results at -20oF conditions for dual-marked 304/304L and 316/316L stainless steel material specimens (hereafter referred to as 304L and 316L, respectively). Recently completed welded material impact testing at -20 oF, room, 300 oF, and 600 oF is also reported. Utilizing a drop-weight impact test machine and 1/4 . Charpy impact test and three-point bending test on 32 mm and 50 mm thick Q690 high-strength steel were carried out according to the environmental features of plateau low temperature to assess the .

Among the medium carbon steel grades, grade S45C (JIS) or AISI 1045 (ASTM) steel is good quality steel with about 0.45% carbon. Type-S45C steel possesses favorable mechanical properties such as .To carry out a standard tensile test on specimens of a hot rolled steel (AISI 1045), Type 2024-T351 aluminum, polymers (UHMW-PE, acrylic) and, from the results, to determine the yield . Specimen (1/2 in. Diameter, ½ in. long or broken Charpy bars) steel, water quenched, air quenched, or furnace cooled (1 per student). . IMPACT TESTING OF .Charpy Impact Test. Full Code MET0102215. Module Type. E-learning. . - Explain an Introduction to Charpy testing, fracture surface appearance, and the history of brittle fractures; - Interpret the effects of a notch, and typical Charpy test results; . steeluniversity. Get in Touch .2 Charpy impact test result of 1018 carbon steel bars Testing media/condition Impact energy (ft-Ib) 3 Testing temperature (C) -196 4 10.0 3.5 10.0 2.5 -78 4.5 Liquid nitrogen (N2()) Dry ice (CO2(s)) Room temperature Boiling water 21.0 24.5 31.5 74.0 33.0 116.8 5 20 105.0 7 100 3 26.0 89.0 119.2 119.5 WQ OQ AC FC Heat treatment conditions (pre annealed 960 C for 1 hr) 3 LO .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

The fracture toughness was estimated from the results of Charpy tests performed on the heat-affected zone (HAZ) of SAE/AISI 1045 steel. In addition, finite element analysis was used to determine the stress state caused by four heavy vehicles (T3-S2-R4 type) localized on one side of the column. 11 The impact test requires a Charpy Impact Machine (Figure 1) that was provided by our engineering lab department, five 1045 AISI steel specimens (Figure 2), liquid nitrogen, dry ice, plain ice, boiling water, and a temperature radar gun. Each specimen was placed into a container filled with either liquid nitrogen, dry ice, plain ice, and boiling water to raise or lower .

charpy impact tester pdf

testing dc current voltage drop electric motors

Jogar Pintar Carrossel, um jogo online grátis de colorir, pintar.

charpy impact test of steel 1045|charpy impact temperature test